We’ve already told you what the CEO of Amazon is up to during his free time. He is busy at Atlantic Ocean digging up NASA’s F-1 engines from the sea floor. This is being done while his world’s largest retail online business is working seamlessly and flawlessly. It’s all about efficiency and making deliveries on time. Unless a system is not efficient, it’s bound to collapse and fail. What makes it possible for Amazon to shift 17 million products within 24 hours and that too successfully without breaking a sweat? Have we ever stopped to wonder about how these things are delivered or where are they kept in a ready-to-ship state? We think not, we just enjoy going through the lists and placing orders, don’t we? Lets have a look behind the scene.

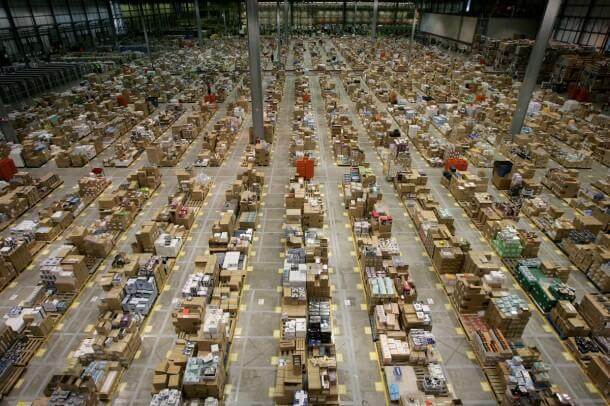

We’ve already told you what the CEO of Amazon is up to during his free time. He is busy at Atlantic Ocean digging up NASA’s F-1 engines from the sea floor. This is being done while his world’s largest retail online business is working seamlessly and flawlessly. It’s all about efficiency and making deliveries on time. Unless a system is not efficient, it’s bound to collapse and fail. What makes it possible for Amazon to shift 17 million products within 24 hours and that too successfully without breaking a sweat? Have we ever stopped to wonder about how these things are delivered or where are they kept in a ready-to-ship state? We think not, we just enjoy going through the lists and placing orders, don’t we? Lets have a look behind the scene. A Reddit.com user has recently published photographs of an Amazon warehouse which shows us how it’s done and where the magic happens. Generally these warehouses are placed strategically close to shipping hubs around the world which makes it possible to make the whole shipping procedure more efficient. Also, these warehouses are huge spaces; over one million square feet as far as the area is concerned. You’d be surprised to know that there are no robots involved and all the work in the warehouse is done manually by 65,000 employees and there are additional 50,000 employees hired during Christmas period to help with the overwhelming shipment orders. Even with that much work force, don’t you think it would be hard to find out where is what? If you look at the pictures closely you’ll notice that Amazon stacks the stuff in a very odd manner. Random products are stacked up together and at the first glance it doesn’t make any sense. But if you look closely and read about the ‘chaotic storage’ concept, things will start to add up and you will be able to grasp how it works. By employing this strategy, Amazon is able to utilize the space more efficiently and it helps them stay flexible. The key idea is this; if you have a space reserved for a certain item only it will remain empty when the stock is low or the item is out of stock and that place won’t be utilized.

A Reddit.com user has recently published photographs of an Amazon warehouse which shows us how it’s done and where the magic happens. Generally these warehouses are placed strategically close to shipping hubs around the world which makes it possible to make the whole shipping procedure more efficient. Also, these warehouses are huge spaces; over one million square feet as far as the area is concerned. You’d be surprised to know that there are no robots involved and all the work in the warehouse is done manually by 65,000 employees and there are additional 50,000 employees hired during Christmas period to help with the overwhelming shipment orders. Even with that much work force, don’t you think it would be hard to find out where is what? If you look at the pictures closely you’ll notice that Amazon stacks the stuff in a very odd manner. Random products are stacked up together and at the first glance it doesn’t make any sense. But if you look closely and read about the ‘chaotic storage’ concept, things will start to add up and you will be able to grasp how it works. By employing this strategy, Amazon is able to utilize the space more efficiently and it helps them stay flexible. The key idea is this; if you have a space reserved for a certain item only it will remain empty when the stock is low or the item is out of stock and that place won’t be utilized. It would be just empty space and that’s a waste. However, using this storage theme that freed up space is utilized almost instantly with other stuff. This way it’s also easier for employees to avoid long walks to a certain item’s storage place because using the chaotic storage, the database can find them the closest set of required item resulting in an efficient storage and less time preparing an order for shipping. Database relies on the use of barcodes that are placed on every item which enter the warehouse. These barcodes are in sync with the storage place where these items are supposed to go in the warehouse. This facilitates the database in keeping a record of everything; what’s coming in and what’s going out and which space is empty or which space has been utilized. Only exceptions to the chaotic storage are bulky furniture and fast moving items which hardly stay at the warehouse before getting shipped. Quite a system, wouldn’t you agree?

It would be just empty space and that’s a waste. However, using this storage theme that freed up space is utilized almost instantly with other stuff. This way it’s also easier for employees to avoid long walks to a certain item’s storage place because using the chaotic storage, the database can find them the closest set of required item resulting in an efficient storage and less time preparing an order for shipping. Database relies on the use of barcodes that are placed on every item which enter the warehouse. These barcodes are in sync with the storage place where these items are supposed to go in the warehouse. This facilitates the database in keeping a record of everything; what’s coming in and what’s going out and which space is empty or which space has been utilized. Only exceptions to the chaotic storage are bulky furniture and fast moving items which hardly stay at the warehouse before getting shipped. Quite a system, wouldn’t you agree?

Comments

Post a Comment

Tell us what you think